Making responsible purchasing affordable

Made In France: Why don’t we make most of our products in France?

Over the last few months, many of you have asked us the same questions:

“When will you start to make your products in France? You claim to be ‘green’ but why are your clothes made on the other side of the world?”

The goal of the following explanation is not to demonstrate that our approach is better than another, but to be completely transparent about our manufacturing and distribution model, including the associated limitations and opportunities. We will also explain how we are able to make a very specific category of products in France.

Let’s start from the beginning:

Since the brand’s creation in 2008, Picture has always sought to make responsible purchasing affordable. We want to reach as many people as possible, especially a large part of the general public that is not actively engaged in the environmental movement.

To make responsible purchasing affordable and the standard, we need to price our products within the range of what the market considers “the norm.”

For example, in the automobile industry, as long as hybrid or electric cars continue to be more expensive than cars that run on diesel or regular-unleaded gasoline, we cannot really make the claim that a “responsible” automobile purchase is affordable. Green vehicles will remain a niche market available only to a small segment of consumers.

The garment industry is in exactly the same situation. At Picture, we want an eco-designed jacket to cost the consumer the same amount as a regular jacket.

With this premise as our starting point, what can we do to make a responsible purchase affordable?

When we launched the brand, our distribution strategy was to work with independent shops and be viewed as an alternative to the major boardsports brands.

The culture and history of our industry (ski, snowboard, surf, and skateboard) have a strong and direct link to physical stores and online shops; they build the actual coonection between brands and the end consumer.

These shops have long played an important role in the local economy and represent thousands of jobs in France and abroad. They maintain a close relationship with the consumer by providing advice and a quality service, as well as by participating in the local scene.

Using a simple product as an example:

100%

Organic cotton used to make a Picture t-shirt

A Picture t-shirt is made entirely with organic cotton. The cotton comes from Söke, a small village in Turkey. The finished product is made 100 kilometers away in Izmir.

We purchase the t-shirt for €7 from our supplier in Turkey, sell it for €12.50 to retailers, who then sell it to you, the end consumer, for €30 to €33, VAT included.

The factory in Turkey that makes the t-shirt is our partner, Seyfeli, a model in Turkey for its labor practices. Picture started working with them right from the start in 2008.

We consider €30 to €33, VAT included, to be a fair price for a cotton t-shirt and similar to other brands in the industry who, for the most part, do not use environmentally-responsible materials. This price allows retailers and Picture to grow in spite of our respective costs: rent, salaries, taxes, customs duties, R&D in France, logistic, and operational costs. In addition, the 20% VAT in France has a considerable influence on our approach.

In this particular case, we could choose to use regular cotton and pay 30% less. However, this would not be in line with our commitment to the environment.

To sum up: 80% of a t-shirt’s value benefits the local economy.

Fournisseur

Valeur :

7€

% de création de valeur :

20% - Étranger

Usage de cette valeur :

Frais de fonctionnement, achat de matières premières, emplois, taxes

Marque

Valeur :

7€

% de création de valeur :

20% - France

Usage de cette valeur :

Emplois, loyers, taxes, logistique, R&D, frais de fonctionnement, impôts

Magasin

Valeur :

24-25€

% de création de valeur :

40% - France

Usage de cette valeur :

Emplois, bail commercial, taxes, logistique, frais de fonctionnement, impôts

TVA

Valeur :

32-33€

% de création de valeur :

20% - France

Usage de cette valeur :

Taxes

And what if we made a t-shirt in France while keeping the same distribution model?

In every case, we would need to source the raw materials outside of France: most of the world’s cotton growers are in India, China, and the United States. Cotton farming does not really exist in France. Once the cotton in hand, we would then be able to spin, weave, dye, and make the product in France.

The cost of labor in France is much higher than in Turkey or China, which means that we would purchase the t-shirt from the manufacturer for €20-€25, sell it for €30-€35 to the retailer, who would then sell it to you for €70-€75 VAT included.

Only a very small number of people would be willing to pay such a high price for a t-shirt. We would stray from our goal to make responsible purchasing affordable.

What would happen if we sold this Made in France t-shirt directly to the end consumer (without a going through a shop or retailer)?

We would buy the Made in France t-shirt for the same price (€15-€20), and once we add our margin, we could sell the t-shirt at a reasonable price.

This is the chosen model for several French brands, such as Hopaal and 1083.

Clément, co-founder of Hopaal explains his approach:

Where would Picture be if we had made this choice from the start?

It’s impossible to say. We think that we would only be a minor player in the boardsports clothing market, since the brand would not be present in the shops that represent the foundation of the industry and where (whether a physical or online shop) consumers go to purchase and enjoy a unique experience, one important to our market.

To conclude, we would have probably been successful in France, our home market. The chosen distribution model is vital to understanding where a product is made. This is a conscious choice.

However, we do make products in France in certain specific cases.

Production for the Picture neck gaiter at the Cenyo factory in Chatillon-en-Michaille, France.

Here is a list of our current initiatives that justify the brand’s environmentally and socially responsible position while manufacturing most if its products outside of France:

Using environmentally friendly and responsible materials (organic cotton, recycled polyester, bio-sourced polyester, reconditioned materials)

Dying processes that reduce energy and water consumption

A durable water repellent finish free of toxic chemicals

Certifications to back up the first three bullet points

A complete and thorough understanding of our supply chain, from raw materials to the finished product

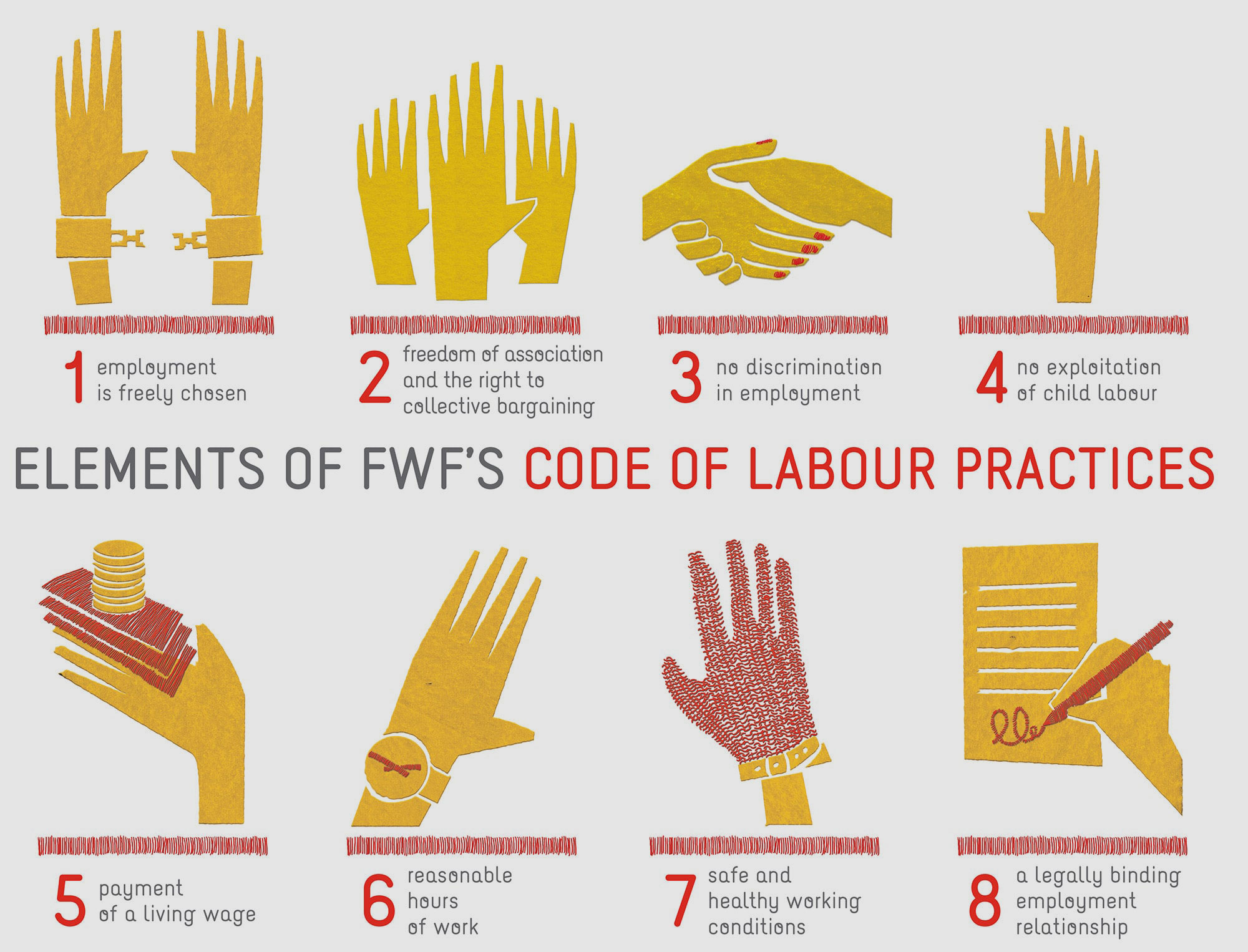

Long-term relationships with our suppliers and partnering with the Fair Wear Foundation to continuously improve workplace conditions for labor

Shipping only by boat to transport products to our warehouses, we never use air freight

We remain, however, far from completely satisfied with our chosen model, and we continuously work to improve each point on the list, sometimes throwing one out for something better.

We hope that this article provides you with a clear understanding of our approach, why we make most of our products outside France, and the resources required to make our garments in our home country. Nevertheless, we very much admire French brands who contribute to giving French factories a new start.